Color Mark Sensor

Color Mark Sensor Manufacturer

As a leading Colour Mark Sensor Manufacturer, Stronger provides innovative Sensors that detect and differentiate colors with high accuracy. Our Colour Mark Sensors are essential for applications in packaging, printing, and quality control, ensuring precise color detection and enhancing product consistency. Stronger’s Sensors are designed to meet the demanding requirements of modern manufacturing processes.

GENERAL INTRODUCTION

Color Mask Sensor applies the light emitting and receiving principle. It will send out modulating light, receivethe reflecting lights from detected object, and distinguish the color or recognize the existence of objects according the intensify of the receiving signals. It can serve for sensor in the automatic control systems for packing machinery, printing machinery, texture and paper making machinery, etc and be used with other instruments to detect the existence of the object marked with color code, pattern code, line or others.

It has the functions of self-locating, recognizing colors, rectifying deviation, pattern checking and countering . The sensor applies optical technique, semi-conductor electronic technique, and modulation demodulation, and has the features of high sensitivity, quick response speed, strong anti-background interference, compact structure and convenient opera ion, etc.

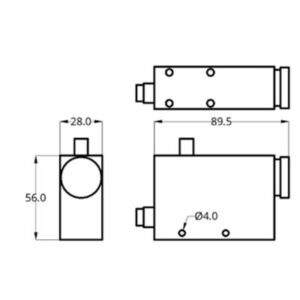

ST-BZJ211

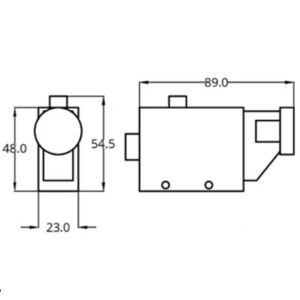

ST-KC22

Color Mark Sensor Product Description Table

| Color Mark Sensor | ST-BZJ211 | ST-KSC22 |

| Size(mm) | 85×57×28 | 89×63×22 |

| Supply Voltage | 10-30VDC | 10-30VDC |

| Ambient Temperature | 0-50 °C | Operation-15° -65° Save- 15° – 80° |

| Detecting Method | Coaxial Reflection | Coaxial Reflection |

| Sensing Distance | 10mm + 2mm | 10mm + 2mm |

| Chromatogram of Light | Red. Green. Blue. White | Red. Green. Blue. |

| Facula | Circular | Circular |

| Response Time | 50us | 0.1 ~ 1ms |

| Output Current | <200mA | <200mA |

| Output Type | NPN | NPN |

| Shell Material | Metal | Engineering Plastics |

| Cable Length | 2m | 2m |

Why Choose Stronger for Color Mark Sensors?

- Cutting-Edge Technology: Our sensors use the latest technology to deliver accurate color detection and reliable performance.

- Versatile Applications: Ideal for use in packaging, printing, and manufacturing industries where color differentiation is critical.

- Custom Solutions: We offer a range of customizable options to meet specific industry needs.

- High-Quality Standards: Every sensor is subjected to rigorous quality checks to ensure durability and precision.

Applications of Color Mark Sensors

Color mark sensors are versatile tools used in numerous applications, including:

- Packaging Industry: Ensuring correct color codes on packaging materials for quality assurance.

- Printing Industry: Verifying color consistency in printed materials and detecting color variations.

- Manufacturing: Sorting and identifying products based on color to streamline production processes.

- Quality Control: Detecting color marks for defect detection and product validation.

Benefits of Using Color Mark Sensors

- High Precision: Accurate color detection ensures consistent quality and reduces errors.

- Improved Efficiency: Streamlines sorting and quality control processes by automating color-based tasks.

- Versatility: Suitable for various industries with customizable options to fit specific needs.

- Durability: Built to withstand harsh industrial environments and provide long-term reliability.

Contact Stronger for Your Color Mark Sensor Needs

At Stronger, we are dedicated to providing top-quality color mark sensors that enhance your operational efficiency. Whether you need standard or customized solutions, our team of experts is here to assist. Contact us today to learn more about our color mark sensors and find the perfect fit for your application.